Product Summary

Test

- Management tool

- SMS and Email alert notification

- Power status notification

- All data logged and stored on server

- Daily status SMS

- Client server interface

- Security access with user name and password

- Level monitoring and temperature of products

- Graphic display of captured data

- Status on request from field unit directly to your mobile phone via SMS

Products

-

4-20mA

Level Pressure Sensor

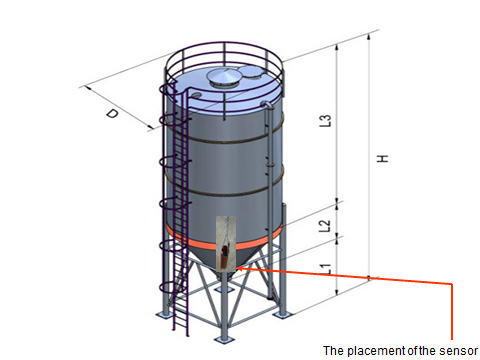

- The sensor is lowered in to the silo threw the man hole

- The sensor is specifically designed for monitoring levels in harsh and highly corrosive and volatile materials commonly used to monitor petroleum

- The sensor is attached into to a steal enclosure for mechanical protection and addition all weights are added to keep the sensor in the bottom of the silo

- The sensor is installed into the cone approximately 500mm – 1m from the outlet

- The placement of the sensor is in such away that the material is constantly passing the sensor plate thus minimizing on a build up and blocking up of the sensor

- Active level monitoring

- Daily status sms with site and silo measurements’ in tons or in percentage

- Assisting with ordering and deliver of products

- Alarm notification for the prevention of overfilling

- GSM based software enabling for live data to be transferred offsite to a central server

- Allowing access to registered users to obtain the stored data

- Data can be viewed in the following ways

- Raw data

- Graphs

- Monitoring of the flow meter by use of 4-20mA flow meters or by a pulse counter

- Monitoring of gasses using relevant sensors 4-20mA or serial sensors

- Main supply monitoring

- Flow rate

- Anti tamper alarm SMS notification

- Logged history captures on our server

-

Scanner

3D Level Scanner

- 3DLevelScanner S for solid applications

- 3DLevelScanner M for solid applications with mapping capabilities

- 3DLevelScanner MV for solid applications with mapping capabilities and visualization (graphics tool)

- The sensor is installed into the cone approximately 500mm – 1m from the outlet

- Multi-Scanner System specifically configured to provide accurate continuous volume measurements of solids stored in very wide silos and other very large open bins, bulk storage rooms, stockpiles and warehouses

- Controlling of the valve via SMS or on a timer

- Controlling of the pump via SMS or on a timer or level from a reservoir

- Staged operation at different positions

- Mains supply monitoring

- Flow rate

- Anti tamper alarm SMS notification

- Pump station status SMS

- Logged history captured on our server

- Monitoring of the flow meter by use of 4-20mA flow meters or by a pulse counter

- Monitoring of gasses using relevant sensors 4-20mA or serial sensors

- Main supply monitoring

- Flow rate

- Anti tamper alarm SMS notification

- Logged history captures on our server

-

4-20mA

Level Pressure Sensor

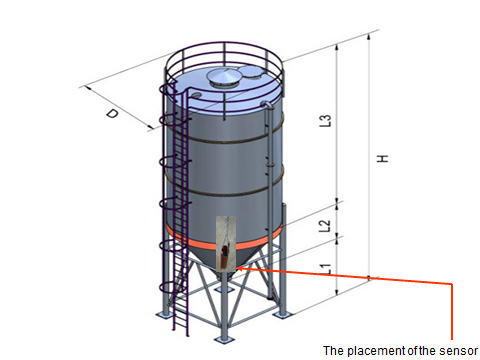

- The sensor is lowered in to the silo threw the man hole

- The sensor is specifically designed for monitoring levels in harsh and highly corrosive and volatile materials commonly used to monitor petroleum

- The sensor is attached into to a steal enclosure for mechanical protection and addition all weights are added to keep the sensor in the bottom of the silo

- The sensor is installed into the cone approximately 500mm – 1m from the outlet

- The placement of the sensor is in such away that the material is constantly passing the sensor plate thus minimizing on a build up and blocking up of the sensor

- Eight, six digit, seven segment display.

- Eight 4 – 20 mA inputs

- This unit connects to our GSM Genie.

- Due to its unique design, you are able to monitor eight silos from one central locations.

- Each channel can be calibrated and linearized by use of a SD Card.

- Model LT 200 load cells manufactured from high grade steel and are epoxy coated for protection.

- The low profile shear web design makes it extremely robust and it has excellent resistance to side and torsion loads.

- Hermetically sealed to meet IP 68 ensures long operation life in adverse conditions.

- Industrial applications include cranes, scale cars, large platform scales, hoppers, tanks, silos and batching systems.